High Transport Capacity Across Multiple Storage Levels

At SMB, we plan and design automated storage systems, specializing in Automated Pallet Warehouses.

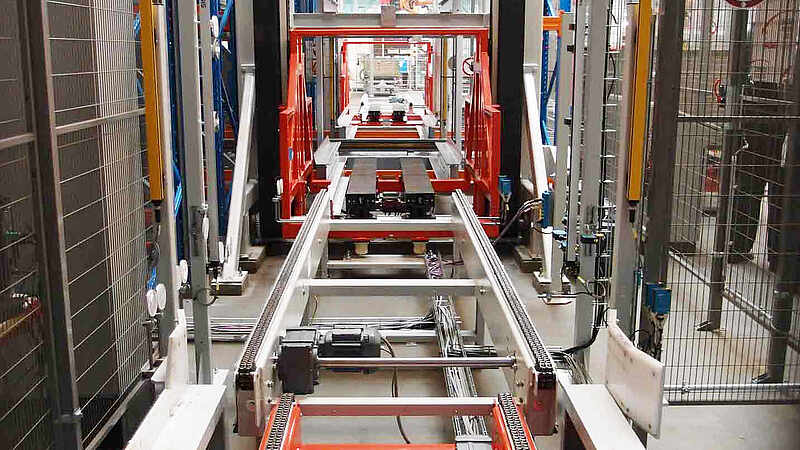

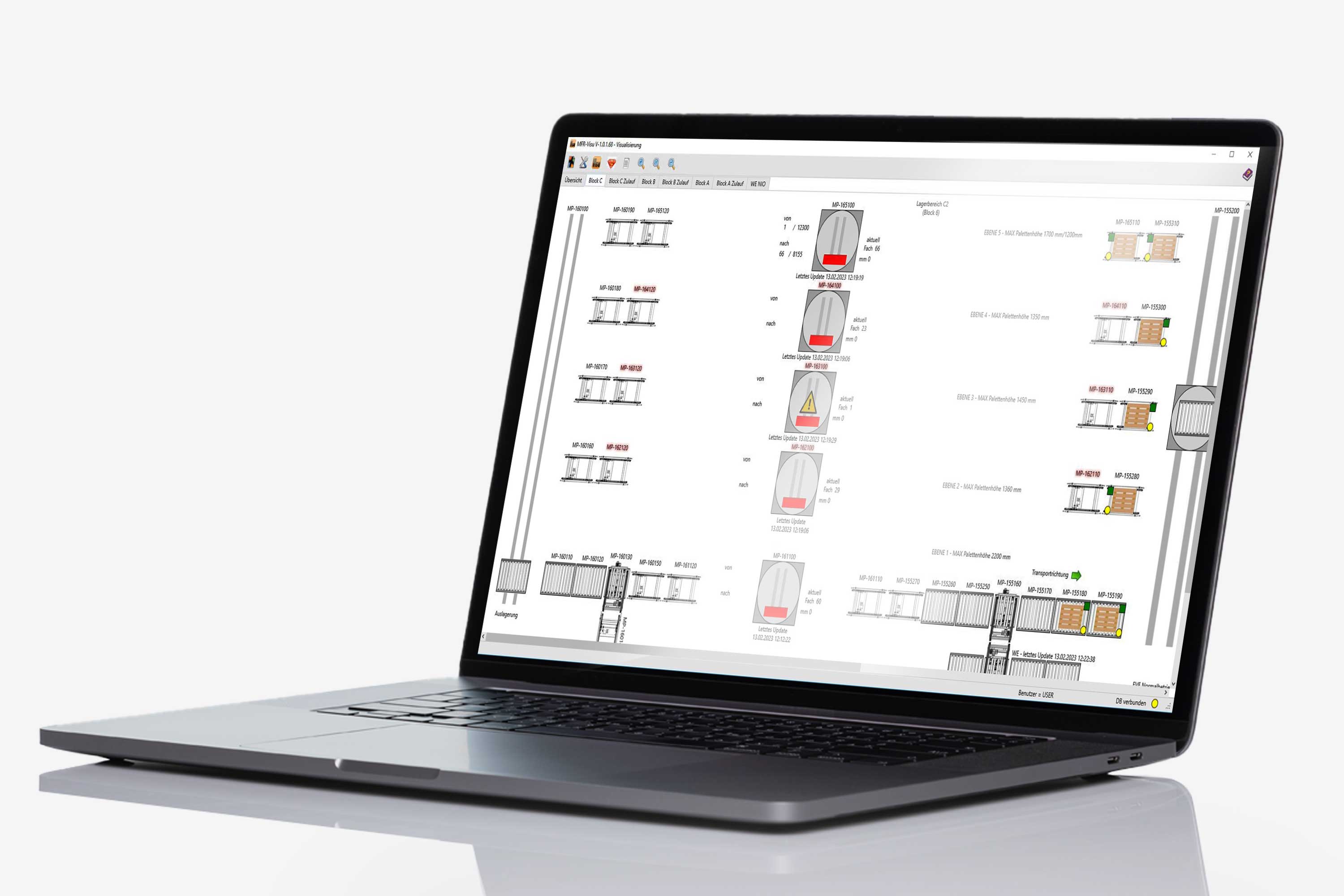

We have developed a fully automated compact storage system with an in-house truck shuttle system. This means high transport capacity across multiple storage levels. Our storage system can be easily expanded with container conveyor technology and combined with an automatic small parts warehouse (SPW). We also program the overarching system control for you, connecting Programmable Logic Controller (PLC) with Material Flow Controllers (MFC) in addition to powerful Warehouse Management Software (WMS).

All storage systems are developed according to your requirements.

The Compact Storage System with Truck Shuttles from SMB

Our fully automated compact storage system offers the highest transport capacity across multiple storage levels.

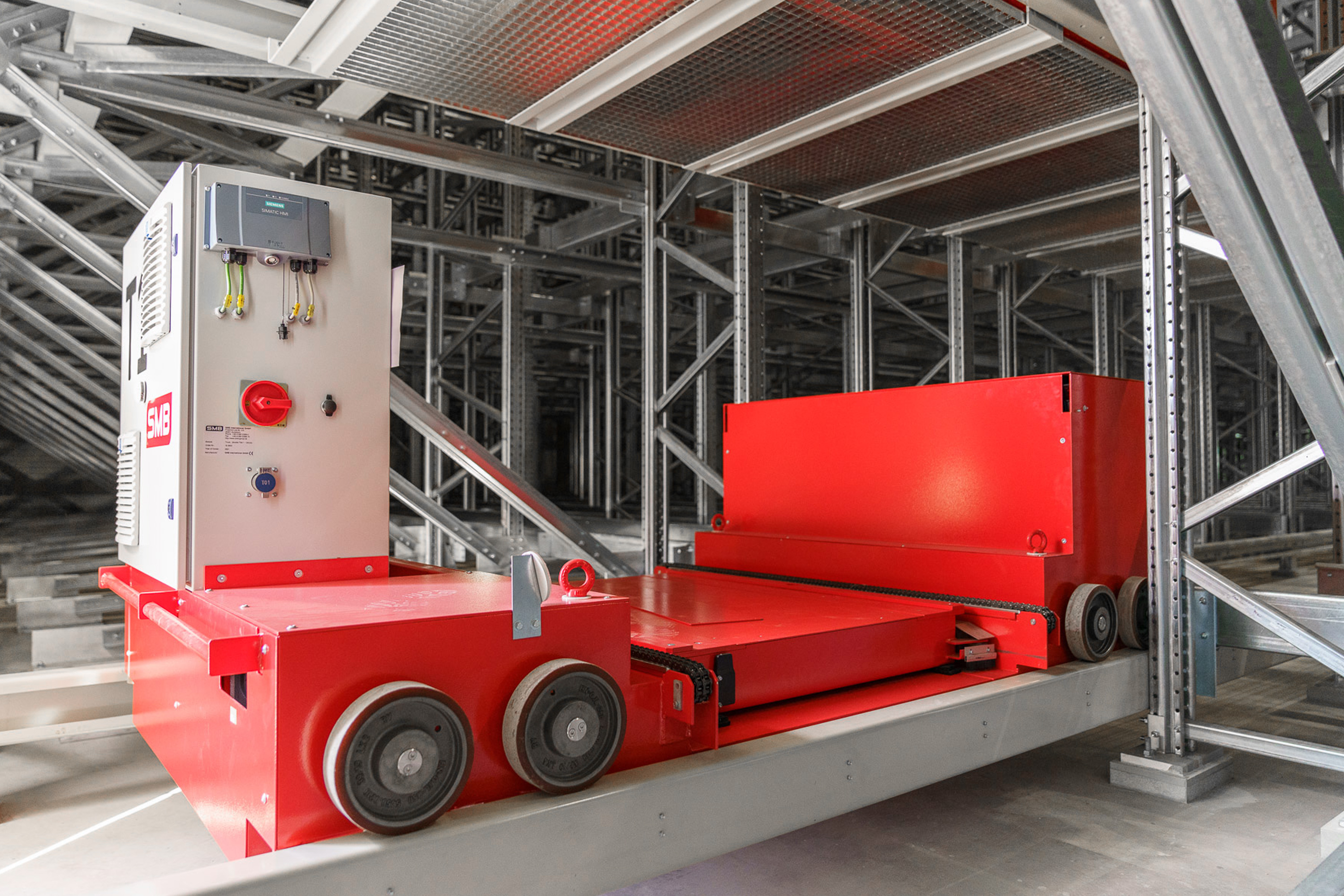

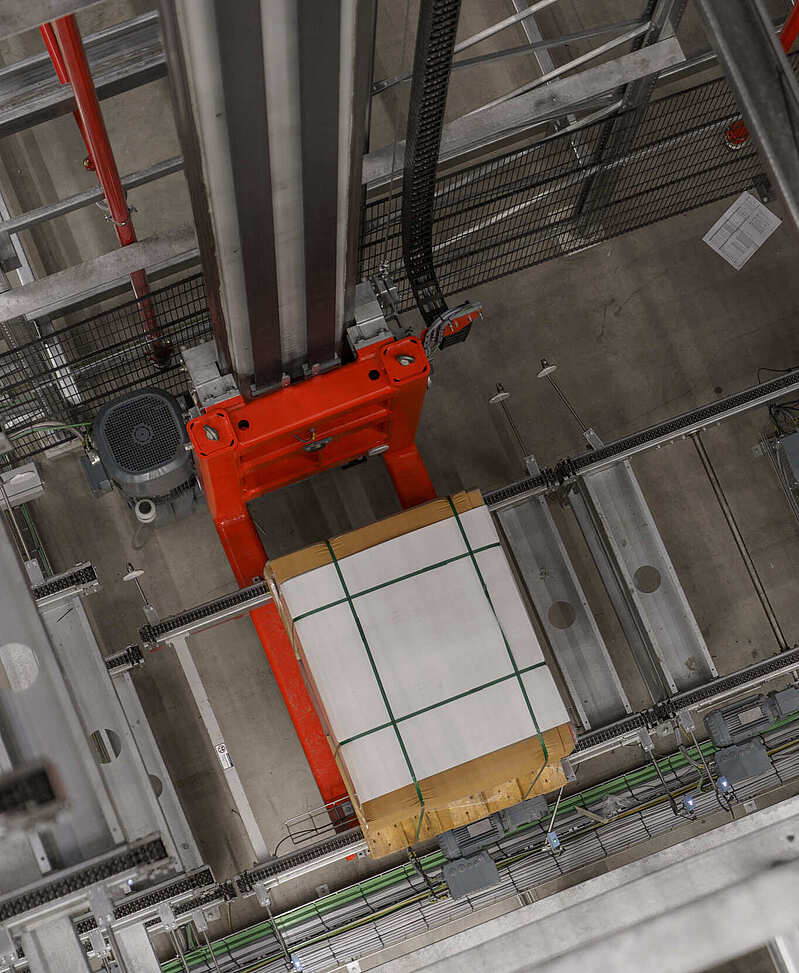

On each level, one or more rail vehicles with integrated pallet shuttles serve the storage channels, handling Euro, industrial, and plastic pallets. Each storage and retrieval device in this truck shuttle system can achieve up to 30 pallet cycles per hour and requires only 6 kW of connected power.

Automated Small Parts Warehouse (SPW)

Not all items stored and retrieved with storage systems are pallets.

Automated small parts warehouses are often part of a larger intralogistics system and are used in combination with Automated Pallet Warehouses. Items are either palletized or depalletized to be prepared for further use. Workstations can be planned at the Automated Pallet Warehouse, or container conveyor technology can be integrated into the overall system.

Our pallet warehouses can be combined with small parts warehouses.

Material Flow Control

How much of what needs to be provided where, when and how?

Material flow control takes care of that by coordinating the storage system. This can be fully automated. We are happy to offer you our in-house warehouse management system, including a material flow controller (WMS/MFC), on a project basis. Alternatively, we can program interfaces to upstream systems. Using simulation software, we can visualize your material flow in advance or test the processes before commissioning the automated storage system.

Learn more about our material flow control solutions.

The Advantages of Our Automated Storage Systems

Outdated storage structures, a shortage of qualified personnel for warehouse management, increased turnover rates, or faster warehouse processes due to business growth – there are many reasons why companies consider investing in an automated storage system.

Automated storage systems are modular and scalable, meaning they can be adapted to the needs of a company. Existing warehouses can be modernized with automated storage systems, and established storage systems can be upgraded by adding new components such as palletizers, filling systems, or conveyor systems for container and pallet transport to create comprehensive intralogistics solutions.

Overall, an automated storage system can help a company achieve warehousing which is more efficient, cost-effective and reliable.

Efficiency is achieved when an automated storage system allows for short transport and walking distances, optimizes the use of available storage space, and guarantees quick access. Speed in retrieval, responsiveness in storage, energy and cost savings through automation, and workplace safety are factors which help determine the storage system that fits.

Details on SMB's Automated Pallet Warehouse

Discover SMB's Automated Pallet Warehouse!

In the intralogistics industry, we're renowned for our fully automated compact pallet storage: the high-performance channel storage with red truck shuttles, the compact distribution vehicles with integrated pallet shuttles.

For more details, visit:

Over the past decades, several automated storage systems have proven themselves in intralogistics:

- Automated high-bay warehouses with stacker cranes or other storage retrieval machines (AS/RS), single-deep, and double-deep

- Automated high-bay warehouses as channel storages (satellite storage)

- Automated compact storage (channel storage with level-bound devices)

- Automated small parts warehouse (SPW) with storage and retrieval machines, single-deep, and double-deep

- Automated small parts warehouse (SPW) as channel storage (shuttle storage)

- Automated container storage (autostore)

All these storage systems are suitable for high-density storage with high storage density and optimal space utilization.

With the increasing automation of systems and warehouse processes, handling devices and vehicles are often driverless. The storage system itself is often controlled by a material flow control software.

Storage and retrieval systems and pallet shuttles enable automated single- and double-deep storage or storage in channels.

The increasing automation of upstream and downstream processes by driverless transport systems (AGVs) have led to more effective use of human resources in the overall operations.

Selection Criteria for Your Automated Storage System

Choosing a storage system for a new build or automating an existing warehouse depends on several factors. Key decision criteria include:

- The desired storage capacity

- The available storage space

- The intended speed for pallet storage and retrieval

- The planned storage method (e.g., fixed or chaotic storage)

- The type or quality of the pallet (e.g., Euro pallets, industrial pallets, chemical pallets)

- The type and weight of the palletized goods (boxes, containers, crates, sacks, barrels, IBC tanks)

- The energy efficiency of the handling devices and the overall system

- The material flow control and warehouse management software

- The costs of acquisition and operation of the storage system

We are happy to advise you on the planning and implementation of your storage system.

SMB is your Project Partner for Warehouse Storage Systems

SMB storage systems offer innovative solutions for the automated storage and retrieval of your raw materials or goods. We specialize in automated pallet storage systems, which we equip with our specially developed Truck Shuttle system.

The basis for optimal storage systems: the individual requirements of your company.

We develop automated storage and retrieval for deep-freeze conditions and as part of larger automated systems. Automated small parts warehouse, palletizers, or filling systems can be integrated. Conveyor systems ensure the connection of the individual parts of the internal logistics chain – creating fully automated intralogistics.

Feel free to contact us about your specific requirements.