What is a Layer Palletizer?

Layer palletizers create pallet units for the storage and transportation of goods by stacking items (e.g., crates, boxes, etc.) layer by layer on pallets. The items are stacked sequentially one on top of the other. The upstream conveyor system aligns the packages prior to placement on the pallet. This means items can be rotated, grouped, or stacked in the product feed.

High infeed: Layer palletizer with product infeed at the top

In a layer palletizer with a high infeed (or top entry) only the pallet itself is moved, shifting up and down in the palletizer. One layer is created and transferred, the pallet moves down, then the next. Once the target height with the correct number of layers is reached, the platform ascends to the conveyance height of the upstream and downstream conveyors. The stacked pallet is released, and a new empty pallet is provided from the roller conveyor. While the finished pallet is being swapped for an empty one, the next set of items are already being prepared. Once the palletizer has raised the new pallet to the start position, the first layer formed during the swap can be transferred immediately.

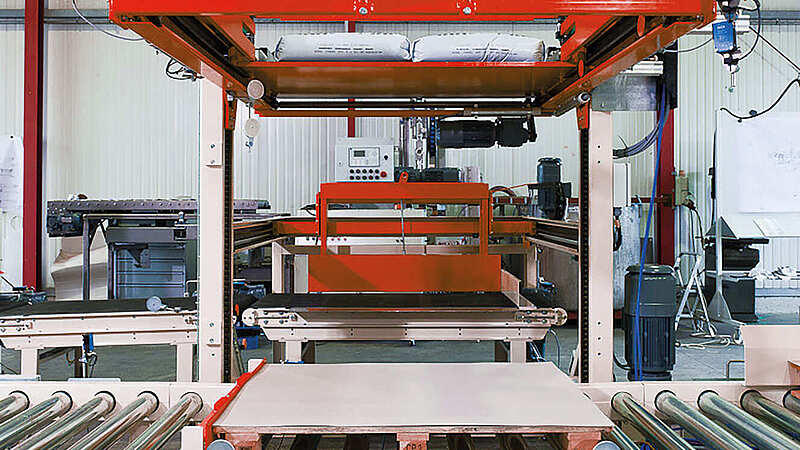

Low Infeed: Layer Palletizer with Product Entry from Below

In a layer palletizer with a low infeed (or bottom entry), the pallet itself is stationary and stays level with the conveyor. The formed layer is lifted at its base by a platform and placed on top of the previous layer. The pallet is assembled from the bottom up. Items can be sent directly to the palletizer's feed without the need for additional conveyor technology (such as lifts, spirals, or elevators).

Empty Pallets, Load Security, and Labels

To enhance automation, our layer palletizers can be seamlessly integrated into a complete pallet system. From empty pallets upstream, to full pallets downstream, we can help you automate almost every step in the process. We can provide the conveyor technology for individual items as well as pallet conveyors. Your palletizer can also be equipped with an empty pallet dispenser (magazine) and systems for securing the load. We are also happy to incorporate machines for further steps, such as stretch wrappers, strapping machines, or labelers.

Empty pallets can be automatically transferred to the palletizer using stationary conveyor systems. Roller conveyors, chain conveyors and pallet shuttles can feed empty pallets to the palletizer and transfer full pallets downstream. This makes layer palletizers an integral part of the supply chain, from palletizing to automated storage.

Automated guided vehicles (AGVs) can partially or completely replace stationary conveying technology between steps in the palletizing process. AGVs provide empty pallets or retrieve full pallets from the layer palletizer. These vehicles transport load units to a stretch wrapper or deliver them to a pallet racking system.

Packing Patterns, Composite Stacking, and Column Stacking

When palletizing layers, choosing the right stacking pattern is crucial. In goods transportation, it is important to optimize pallet volume while maintaining the stability and safety of the load. Stacking interlocked or clustered items can help achieve this balance. Our layer palletizers can achieve such packing patterns with precision and speed. We refer to this as interlocking. For goods with uneven bases, we recommend column or tower stacking, such as for beverage or dairy crates, open trays with stacking lugs (commonly used in bakeries).

The optimum layer pattern of a pallet is achieved as soon as the packing area is utilized to the maximum and load securing is still guaranteed. Cuboid packages are therefore usually palletized in layers. The palletizer arranges the packages on the pallet according to a specified layer pattern. Once a layer has been palletized, the palletizer stacks the next layer on top. The packing pattern is based on setting patterns, which can look very different depending on the dimensions of the packages.