Data Exchange Between the Warehouse Management System and the Controller

SMB's Automated Pallet Warehouse is equipped with a specialized Material Flow Controller (MFC) that is designed for the storage operations of our high-performance pallet flow rack. The software handles the data exchange between the warehouse management system (WMS) and the programmable logic controller (PLC) of the Automated Pallet Warehouse.

The Task: Automating the Transfer of Pallets to Storage Locations

The system control receives transport commands from the warehouse management system and forwards them to the conveyor systems of the warehouse. Moreover, our Material Flow Controller handles transport management in the Automated Pallet Warehouse. The MFC software calculates potential storage paths in the live warehouse and finds the ideal spots for European pallets, industrial pallets, and plastic pallets on homogenous or mixed storage racks.

To transport a pallet to the intended location in the SMB Automated Pallet Warehouse, the system control can use vertical conveyors and several storage and retrieval devices - truck shuttles - on each level. Since storage and retrieval processes in the Automated Pallet Warehouse take place quickly and in parallel, large volumes of data need to be managed and processed in order to calculate the material flow steps.

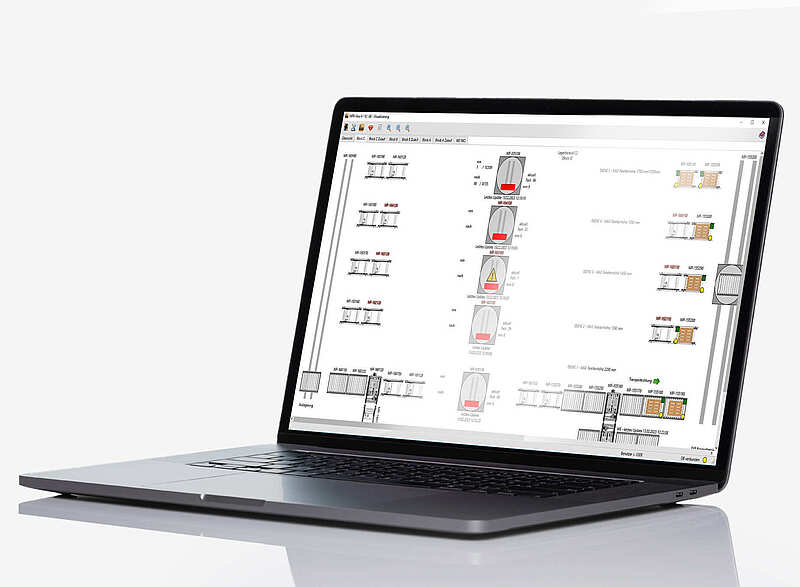

Our Material Flow Controller is connected to the machine control of the SMB Automated Pallet Warehouse via an interface. The data points of the PLC are mirrored and visualized in the Material Flow Controller. Using field data, the MFC software calculates possible transport routes to the positions and issues appropriate commands to the PLC of the pallet warehouse.

The pallets then move on conveyors until they have reached their (interim) storage space. Any interruptions along the way are reported by the Material Flow Computer to the warehouse management system, which can help identify alternative routes and storage locations.

Do you want to use SMB's Automated Pallet Warehouse with another WMS or MFC?

Our Material Flow Controller combined with our warehouse management system WMS/MFC allows for smooth automation within our Pallet Warehouse.

The PLC of the SMB Automated Pallet Warehouse can also be used with warehouse management systems and material flow controllers of other software providers. For instance, we are successfully using our machine control in combination with our partner KBU Logistik's warehouse management software. If you already utilize proprietary solutions for warehouse management or material flow management in your company, we are happy to create the required PLC interface.

Tell us about your preferred software tools!

The tasks of a Material Flow Controller can differ depending on the industry and size of the project. From control of the storage and retrieval process in a small parts warehouse to the complex networking between a production plant with a palletizer and an automated pallet warehouse; we can handle both simple and complex integrations.

The control of and communication between conveyor systems, such as our transfer and shuttle vehicles, automated storage and retrieval systems (AS/RS), and AS/RS with pallet shuttles, and hence the entire internal material flow, are core competencies of the system. Through the visualization of these processes, staff can monitor the material flow at all times and intervene manually when needed.

The MFC Can Be Customized

If you want to increase the degree of automation in your intralogistics, you need intelligent control systems. A Material Flow Controller tailored to your warehouse system is the foundation for the smooth automation of your intralogistics. The SMB Material Flow Controller is the optimal software solution to control and optimize the material flows in the Automated Pallet Warehouse.

All of our warehousing strategies are designed for high performance and capacity. It is possible to customize the material flow calculations according to your requirements and send them to the control system.

Proven Warehouse Strategies Our MFC Uses

- Capacity search for dedicated or dynamic storage

- Space allocation according to customer criteria (e.g., batch, best before date, serial number, temperature)

- Search for optimization locations, for example, in mixed racks.

- Consolidation of the warehouse (e.g., moving pallets onto dedicated racks)

- Retrieval of batches into different areas (e.g., FIFO and FEFO)

- Multi-level space allocation

- Finding shortest routes with a minimal number of relocations

- Space utilization down to the millimeter

- Mixed pallet management

Unique Features of the SMB Material Flow Controller

- Fully automatic control of warehouse operations including tracking of the entire warehouse process

- Networking with other systems using intelligent information and communication technologies

- Interfaces to conventional ERP systems and warehouse management systems

- Integration into different warehouse management systems possible, even during ongoing operation

- Modular construction which allows for the addition of new features and functions