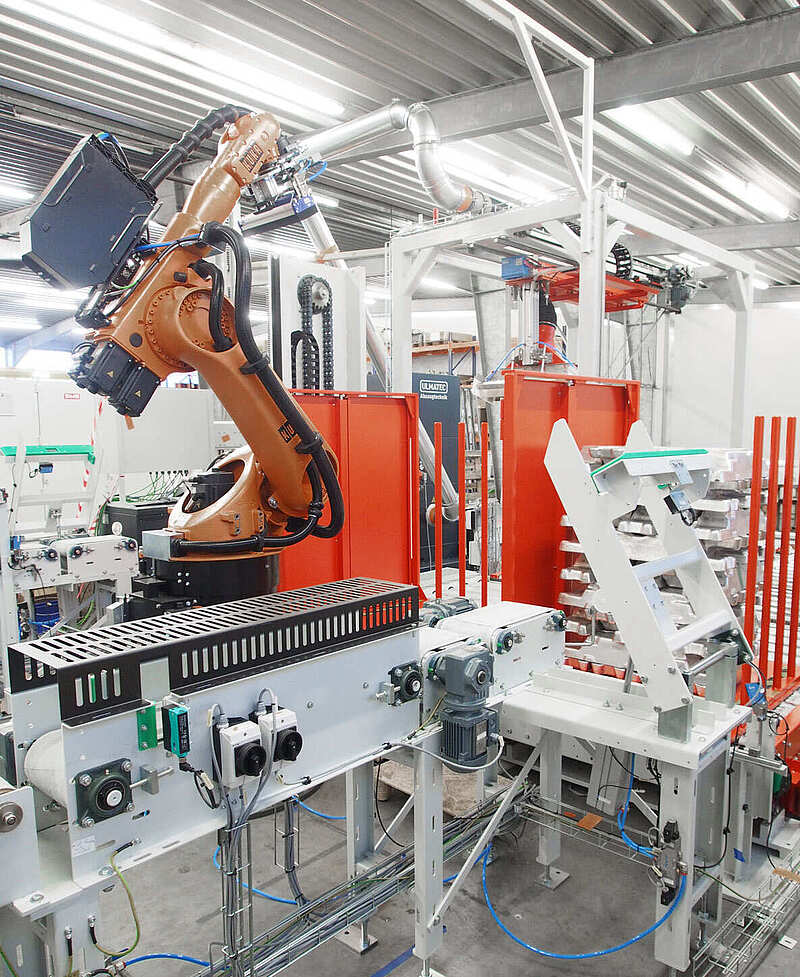

Palletizing with Gantry or Articulated Arm Robots

Our palletizing robots are advanced load handling systems equipped with customizable gripping elements. When paired with the right feed system for your products, these devices automatically stack or unstack wrap-around boxes, American-style cases, crates, bags, or even 120-liter drums.

Customized Palletizing with Gripping Tools

Discover how gantry robots, articulated arm robots or cobots can streamline your palletizing tasks in production and intralogistics.

Our palletizing robots are equipped with various gripping tools. Explore the additional features of our bag palletizers and drum unloaders:

Our Palletizing Robots: High Packing Performance, Flexibility, and Customization

Regardless of the handling task or type of container, our palletizing robots place goods on pallets quickly and precisely. Their high packing performance is just one reason to incorporate robotics into palletizing processes.

Furthermore, our palletizing robots offer maximum flexibility and customization for specialized material handling tasks. Our palletizers come with various gripping systems and efficiently handle complex tasks in tight spaces.

This is made possible through custom programming of the robots, a service we are also happy to provide for you. Learn more on this page about some of our realized projects in robotics and our palletizing robots.

- Gentle material handling with grippers to protect products

- Space-efficient design

- Customizable gripping elements

- Modularly compatible with SMB's automatic pallet storage system

Types of Palletizing Robots

What types of palletizing robots are available?

We have compiled a brief overview for you.

Articulated arm robots are suitable for palletizing and depalletizing tasks where high performance or speed is required. The pick-up and drop-off points are positioned close to each other to minimize unnecessary movement of the robot. However, additional pick-up and drop-off points can be arranged within the robot's working area, but these must be considered in the robot's performance assessment. The use of a linear axis can significantly extend the robot's working area, enabling the execution of similar tasks as with a gantry system.

Articulated arm robots are categorized into four-axis robots or six-axis robots:

Four-Axis Robots are the typical palletizing robots for which the additional axes are not necessary.

On the other hand, Six-Axis Robots are used when handling or palletizing tasks become more complex, such as in confined spaces or with inclined conveyance systems and slanted roller conveyors or belt conveyors.

Gantry robots (or linear robots) can significantly enhance the utilization of space in production or intralogistics work areas. They handle the automatic loading and unloading, rotating, and transferring of packages onto carriers. Since they operate from above, the space required for a linear axis, as needed by articulated arm robots, is not necessary. Pick-up and drop-off points can be positioned very close to each other, which greatly reduces the space needed in production. With the right feeding system and gripping mechanism, a wide variety of applications can be combined, and a broad range of load capacities can be addressed, such as in:

- Box and crate handling

- Empty pallet handling

- Picking

- Depalletizing

- Palletizing

With custom gripping systems, gantry robots can perform multiple tasks simultaneously, such as handling boxes and pallets or performing both palletizing and depalletizing. If boxes and crates can be gripped, lifted, or placed in a row, the performance of the gantry robot can be significantly increased.

Palletizing robots equipped with vacuum grippers are usually the fastest palletizing systems. They eliminate the need for additional movements like clamping or sliding under, thus achieving high cycle rates per minute.

Collaborative robots (cobots) are robots designed to operate without safety fences so they can work in close proximity to and with humans. In that sense cobots are industrial robotic palletizers used for simple handling and palletizing tasks where space is limited, and both the power needed and weight of the packages are limited.

Gripper Types

The grippers of a palletizing robot vary depending on the handling task of the palletizing system and the number of units to be handled simultaneously. Whether magnets, surface interlocking, pneumatics, or mechanics are used in the gripping mechanism should be chosen based on the characteristics of the goods.

A vacuum gripper uses suction to pick up packages with smooth surfaces from above and places them onto pallets. Suction grippers are often used for stacking lightweight packages. However, SMB has also adapted a gripper for a vacuum palletizer that can handle drums up to 120 liters.

Palletizing robots with clamping grippers grip light to medium-weight units with two gripping elements. To pick up the packages, they are either positioned on feeders compatible with the gripper or lifted by pneumatics. To reduce the clamping force on the packages and to increase stability, the gripper can also be equipped with an additional lower grip.

Fork grippers pick up units either by sliding them onto fork-like rods or by having the forks dip below the feeder and waiting to pick them up. When placing the units, the fork moves away in a retracting motion. This design is primarily suitable for heavy units or those that cannot be handled by using clamps or suction, such as open trays. Fork grippers require special pick-up tables with gaps shaped like the gripper forks. Sufficient space is needed to allow the forks to retract after placing the units down.

With the combo grippers developed by SMB, not only can units be handled, but pallets or packing materials (protective cardboard, interlayer cardboard) can also be placed. This functionality supports all common pallet formats (e.g., Euro pallet, industrial pallet, CHEP pallet, plastic pallets, hygiene pallets).

Components and Functions of a Palletizing Robot

A palletizing robot is a technical system designed for the automatic loading of pallets with units of various sizes. There are numerous types of robots and robotic palletizing systems, all developed with the specific tasks in production and intralogistics in mind.

Typically, a palletizing robot consists of several components. These include a pickup station (pick place) with a feeder, a handling unit (manipulator or gripper), and a placement station (pallet). With a palletizing robot, it's possible to form layers on a pallet in two or three dimensions. Therefore, palletizing robots are used for handling uniform pallets as well as mixed pallets or order-picking pallets.

In addition to palletizing or depalletizing, the robot can perform additional tasks, provided that the gripper is equipped with the necessary functions.

Common additional tasks for palletizing robots include:

- Automatically placing pallets

- Placing protective cardboard on pallets (for example, for delicate products like flour and sugar or hygiene products)

- Placing interlayer cardboard for load stabilization

We are a Kuka System Partner

For several years now, SMB has been developing and implementing palletizing robots in collaboration with Kuka Robotics; we are an official Kuka System Partner. Our partnership allows us to create and implement custom solutions based on client needs. Often, these palletizing robots are part of a complex system, which might include conveyor systems or filling stations.

Are you interested in palletizing robots from other companies like ABB, Yaskawa, or FANUC? Let us know your preferred robotics partner. Together, we will find the right solution for you and tailor palletizing solutions to meet your specifications.

SMB is your Project Partner for Palletizing Systems

SMB's palletizing systems can process different types of containers and pallet unit loads and create precise layer patterns and stable packing patterns. Different pallet types are just as little a problem for our palletizers and repalletizers as varying load carrier sizes.

The basis for optimum palletizing systems: the individual requirements of your company

We make palletizing under clean room conditions possible as well as combining it with a production and packaging line, a filling system or an Automated Pallet Warehouse. Fully automated internal logistics chains are thus created via conveyor systems.

Please contact us with your specific requirements.