Optimize Material Flow with Continuous Conveyor Systems

Pallets enter and leave the warehouse on a regular basis, making them a central component of intralogistics. The pallets are often moved using manually-operated equipment, like pallet jacks or forklifts. These methods are intermittent and require trained personnel. The alternative is a continuous pallet conveyor system, which ensures reliable operation, high throughput, and increased safety for all employees.

When to Use Pallet Conveyor Systems

Pallet conveyor systems are ideal when pallets frequently travel the same routes within a facility.

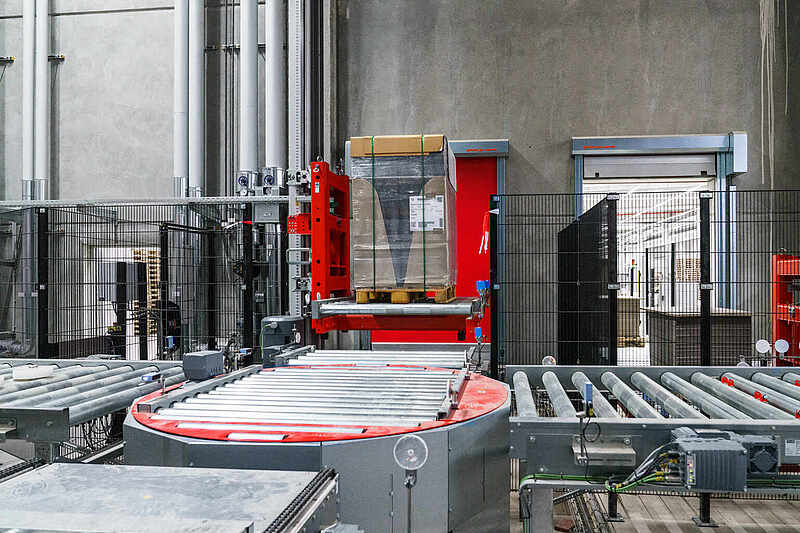

These systems operate efficiently and cost-effectively, automating the initial stages of intralogistics. For example, upon arrival at the facility, roller or chain conveyors can automatically transport pallets to a pallet exchanger, where the load is transferred to the internal transport system. The pallets then continue through the various stages of the logistics chain.

Pallet conveyor systems form the essential connections in this process.

SMB’s pallet conveyor technology can be used for a number of applications. With a range of components, from pallet transfer systems to specialized shuttle cars, these conveyors can navigate any route within your facility. Like pieces of a puzzle, the individual components fit together to create a seamless logistics chain. Pallets can travel long distances at high speeds, and the conveyor paths can be designed to handle curves, inclines, or tight spaces.

Roller Conveyors

Pallets can be automatically transported on rollers across all areas of your facility. Both long distances and complex paths, roller conveyors can be used for various tasks and customs solutions. These continuous conveyors are robust and ideal for handling rollable pallets and unit loads.

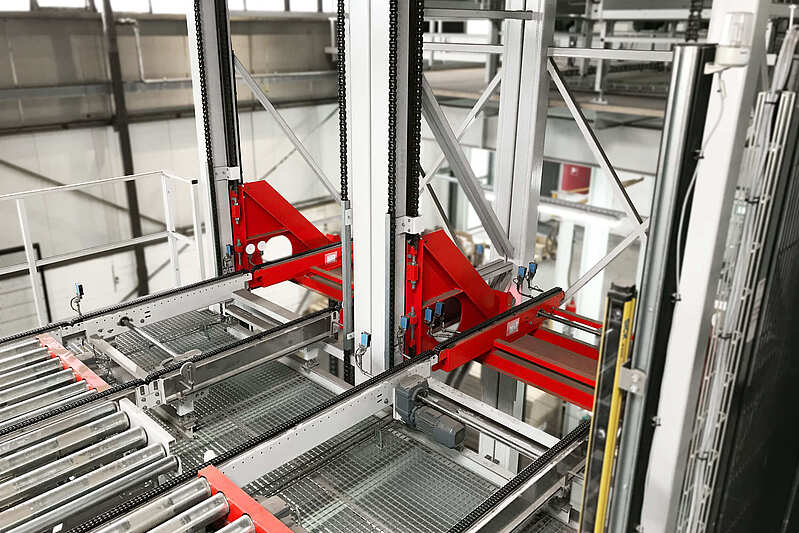

Chain Conveyors

Pallets can be moved quickly and reliably throughout the facility using chain conveyors. Whether it’s straight paths, curves, or inclines, chain conveyors ensure that pallets reach their destinations efficiently. These continuous conveyors use a chain drive and are also known as chain-driven conveyors. They are suitable for both horizontal and vertical pallet transport.

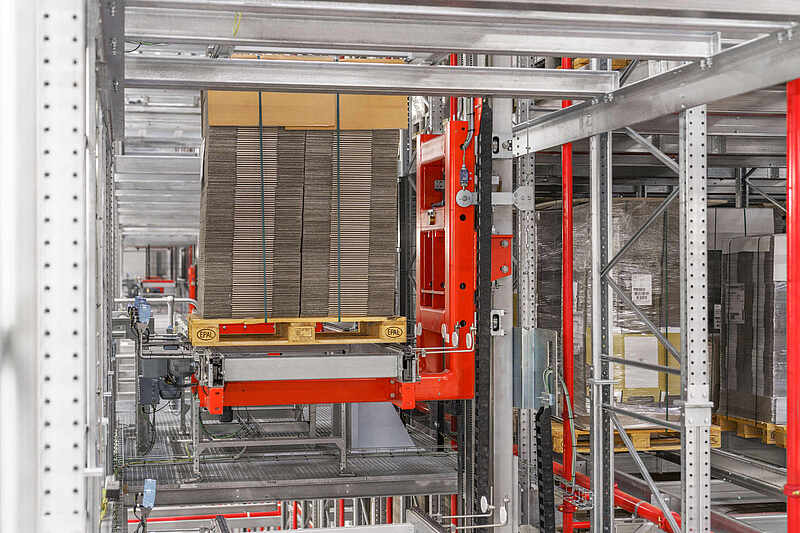

Vertical Conveyors

Vertical conveyors are used to move pallets up and down to different levels. Using the available height helps unlock the full storage potential of facilities. Vertical conveyors, also known as lifts or elevators, can operate as continuous conveyors (like a paternoster) or as stop-and-go conveyors (like an elevator).