Our fully automated, high-dynamic storage system solution

In our Automated Pallet Warehouse, all individual elements – from storage technology and handling devices to conveyor systems and software – are perfectly coordinated to ensure that all your warehouse processes run seamlessly:

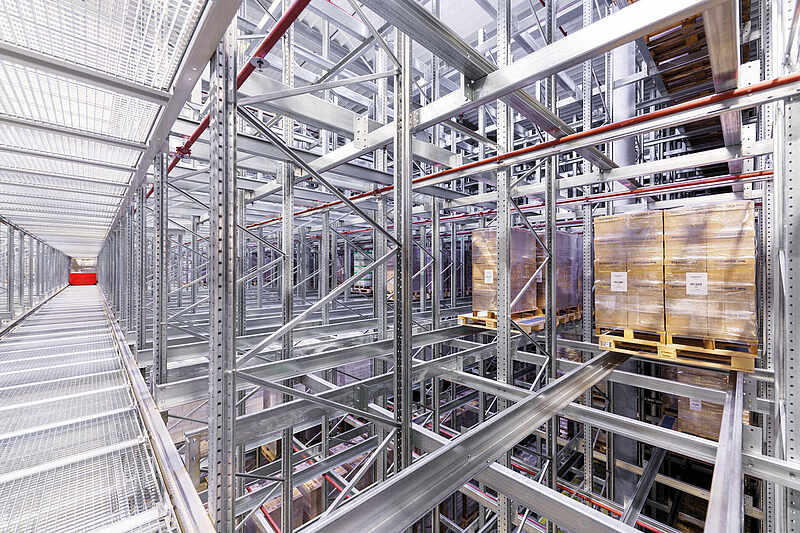

- Fully automated channel storage for maximum space utilization, even in tight areas

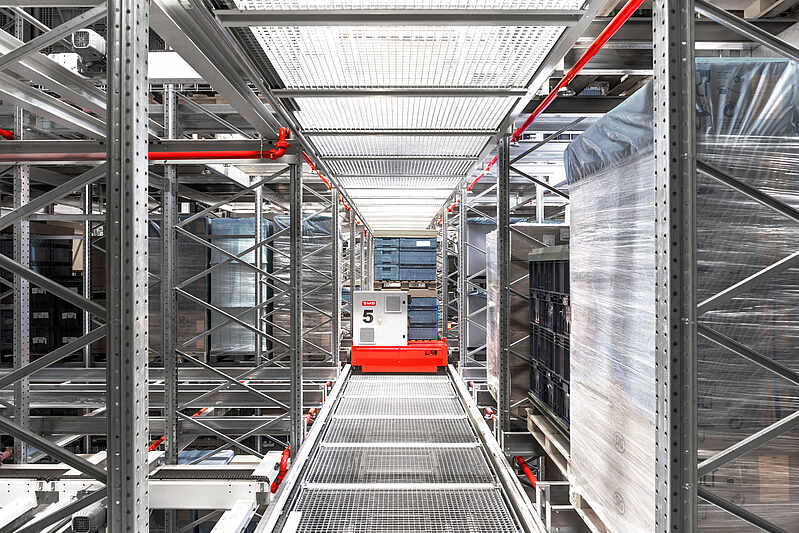

- Truck-Shuttle System – at least one dedicated distribution vehicle with integrated chain conveyor and pallet shuttle per storage level

- High system performance and redundancy

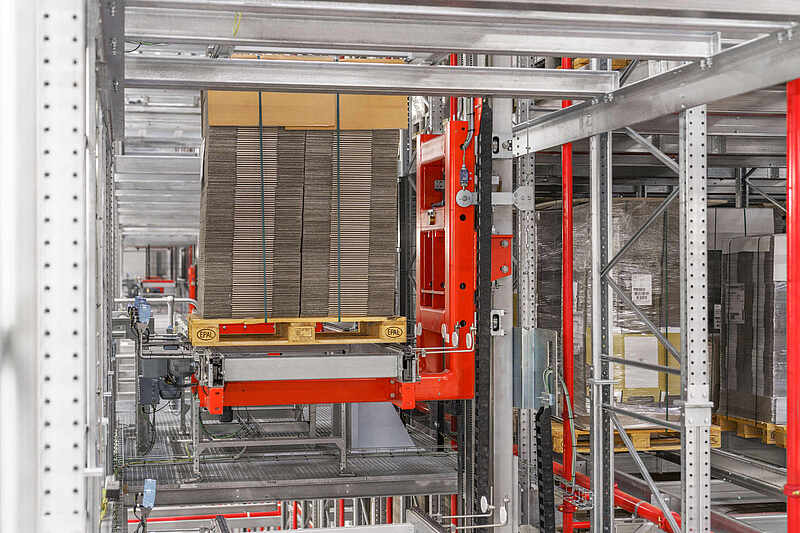

- Vertical conveyors to distribute load carriers on each storage level

- Material flow control software and system simulation

- Programmable logic controller (PLC) with an interface for the warehouse management system

- Warehouse management system (WMS) and material flow controller (MFC) in one application

- Project-specific interfaces tailored to the customer’s system

The result is a compact and automatic storage system for your pallets. With our Automated Pallet Warehouse, we bring high performance to your company's intralogistics. Contact our technical sales team for a non-binding offer.

We came up with the idea for our automated channel storage with Truck Shuttles over 15 years ago.

A customer in the packaging industry needed an automated pallet warehouse with high performance and availability for the storage and retrieval of seasonal goods. We equipped their channel storage with a dedicated distribution vehicle on each storage level and integrated pallet shuttles for loading the side storage channels. These were the prototypes for our Truck Shuttles.

In our Automated Pallet Warehouse, multiple handling devices and shuttles serve the storage channels.

To raise the pallets to the individual storage levels, we developed vertical conveyors which pass the pallets to the Truck Shuttles on the corresponding levels.

In combination with pallet conveyors, the Truck Shuttles, and our customized machine control software, we were able to significantly speed up the storage and retrieval process and found a way to improve storage density during operation. Our Automated Pallet Warehouse was born.

Today, our automated storage system has made the pallet warehouses for many customers more robust and efficient.

From custom-engineered machines to a standardized pallet warehouse

Over the years, we have further professionalized our Truck Shuttle System. We can integrate several storage and retrieval machines on any number of storage levels. We also take care of the entire project planning and implementation of the compact storage system at the customer's company.

Contact us for the automation of your pallet warehouse!

Additional Application Examples

- Raw or finished goods storage in production facilities

- Production supply

- Import and export – such as container goods

- Parts of a warehouse for A-items (B- and C-items in other storage systems), packaging materials (such as cartons)

- Quarantine storage routes

- Consolidation of external warehouses

Functional Process of the Automated Pallet Warehouse

How does SMB's Automated Pallet Warehouse system work, and how are the pallets moved within it?

Fully automated, all goods are always at hand quickly – this is the result of our automated storage technology. The compact storage system developed by SMB is an automated system designed specifically for pallets. It is based on channels with multiple pallets being stored one behind the other in a row.

- Pallet transfer, confirmation, mechanical centering

- Pallet and scanning

- Contour and weight check, if necessary

- Pallet transport to the target level via vertical conveyor

- Pallet transfer from vertical conveyor to buffer

- Pallet transfer from buffer to Truck Shuttle

- Truck Shuttle travels with the pallet to the target channel

- Shuttle travels with the pallet to the storage location in the target channel

- Shuttle returns (empty) to the Truck

Larger Quantities and Higher Turnover in Warehouse Operations

The SMB Automated Pallet Warehouse offers an individual solution for pallet storage. Its advantages come into play from a project size of 1,500 pallet spaces (PSP). However, solutions can also be implemented for up to 30,000 pallet spaces and larger, whether as an in-house or silo variant.

High Degree of Automation and Storage Density

Each storage level has a dedicated Truck Shuttle that transports pallets to their storage locations. Vertical conveyors raise the pallets to the corresponding storage levels. This creates an automated pallet warehouse with high system performance and redundancy.

High Speed in Storage and Retrieval

One Truck Shuttle per level allows for storage and retrieval on multiple levels simultaneously. The Truck Shuttle fully lifts and moves the pallet from one location to another. Redundant storage ensures that pallets from the same batch are distributed across multiple levels, allowing for fast, direct access.

In/Out Frequency: Up to 130 Pallets per Hour

Depending on the number of storage levels and Truck Shuttles used, the turnover rate can be increased substantially.

Accelerated Storage and Retrieval

We use vertical conveyors for the quick provisioning and retrieval of pallets on individual storage levels, accelerating storage and retrieval – for example, for seasonal goods.

Over 95 Percent Space Utilization

In round the clock operations, our warehouse rearranges the pallets so that the most frequently used goods are also the most accessible. Intelligent pallet relocations help achieve a higher storage density. This allows for an exceptionally high utilization of the available spaces on a small footprint.

Suitable as a Pallet Storage System for Frozen Goods

Forgoing batteries makes true 24/7 operation possible, even in deep-freeze warehouses. The individual storage levels can be switched off separately, ensuring safe access during service and maintenance while continuing the operation of the other levels.

High Storage Capacity Even with Mixed Pallets

With strict batch FIFO and batch FIFO in mixed channels, our Automated Pallet System always achieves an occupancy rate of over 90 percent. Using the standard handling device and individual pallets (from Euro pallets to drum pallets with a maximum of 1,500 kilograms) in mixed storages, space utilization rates of 95 percent or higher can be achieved by integrating individual pallets in standard mixed storage.

Optimal Storage Density, Regardless of Storage Structure

Thanks to years of experience operating our warehouse management system with an integrated material flow controller, we are able to achieve a high space utilization rate, even with a mixed item or pallet structure. Therefore, the system is ideal for combining both batch and individual space access.

Project Planning and Implementation from a Single Source

We provide you with the complete steel construction for the channel storage system tailored to your needs, multiple high-performance handling devices for any number of storage levels, and pallet conveyor technology - all made in house. In project planning, we handle the overall planning of your systems – from the receiving dock to the shipping dock.

High Degree of In-House Production

We manufacture our systems in Germany based on robust mechanical engineering. The use of maintenance-friendly standard components helps keep our intralogistics solutions dynamic, flexible, and productive.

Clear Safety Advantage Over Mast Devices

In the event of process disruptions, it is not necessary to shut down the entire main aisle. The TÜV-certified access concept ensures that each individual level of the automated pallet warehouse is accessible. Disruptions can be resolved without having to completely shut down a main aisle.

Energy-Efficient Truck Shuttles and Vertical Conveyors

Our pallet storage system sets standards in efficiency. A Truck Shuttle, with a tare weight of around one ton, move pallets with the same weight and individual weights over one ton while only using 6 kW of continuous power.

In contrast to conventional storage and retrieval systems, which can weigh up to 30 tons and require at least 70 kW of continuous power, our pallet shuttle offers energy-efficient and redundant storage and retrieval. The Truck Shuttles work as precisely as they do quickly, achieving up to 30 pallet cycles per hour.

Vertical conveyors, which weigh around 12 tons, move pallets up and down to the respective levels for transfer to the Truck Shuttles and require 70 kW of continuous power.

Truck Shuttles as Storage and Retrieval Devices

Each Truck Shuttle functions as a transport vehicle and pallet shuttle in one. The key feature is the autonomy of the individual vehicles. While in other storage systems, a storage and retrieval device handles all levels of an aisle, in our pallet warehouse, multiple Truck Shuttles independently store and retrieve goods based on precise instructions from the material flow control system. Intelligent storage and retrieval maximize performance.

Pallet Shuttles Integrated into Each Storage and Retrieval Device

The pallet shuttles integrated into our storage and retrieval devices are the transport vehicles that load the storage channels with pallets. They travel along rails into the channels and place or remove load carriers for storage or retrieval. They are permanently powered by a power rail.

Pallet Racks

We build pallet racks in existing warehouses or new builds. The rack uprights, girders, spacers, and channel rails of our channel storage system are made of galvanized steel and manufactured in Germany. The space-saving design of our Automated Pallet Warehouse makes our pallet racks an optimal storage solution for buildings with unique architecture or limited space.

Today, a warehouse is not just a place where goods are stored and retrieved manually. In modern automated warehouses, software is used to plan and control the storage, retrieval, picking, and staging of goods with assistance from machines. The fully automated processes are checked and optimized, and inventory levels are recorded in real time. To achieve all this, you need state-of-the-art storage technology. An Automated Pallet Warehouse has this capability.

We develop each of our storage systems individually and are a one-stop shop for all of the components needed to build and implement an Automated Pallet Warehouse.

First, we analyze the warehouse data and use it to develop a model. Once all of the key markers are defined, a digital simulation of the entire warehouse is created. This forms the basis for further development in collaboration with our customers. If necessary, we can optimize individual components of the Automated Pallet Warehouse and plan the integration of other storage systems, such as a small parts storage warehouse (SPW), or of our conveyor systems.

Once the concept is finalized, the implementation can start: The complete pallet warehouse is first manufactured in Quickborn, partially pre-assembled, and tested. The installation takes place on site, which is followed by rigorous testing.

The end result: a turnkey solution.

We offer in-house material flow control software that combines the warehouse management system (WMS) and material flow controller (MFC). A standardized interface to the programmable logic controller (PLC) is also part of the integration. We also provide connections to all common enterprise resource planning (ERP) systems. We can also connect the machine control of our Automated Pallet Warehouse with the material flow controller already in use at your company.

Our Automated Pallet Warehouse is comparatively lightweight, meaning the required load-bearing capacity of the floors is low. As a result our system can often be built in existing warehouses. As a complete new build, it can also be implemented as a roof- or wall-supporting rack – an industrial floor is sufficient as a base. Additionally, the technology is very quiet and can be operated in open-concept warehouses.

All levels of our Automated Pallet Warehouse integral to the full automation of the warehouse, however they can still be switched off and accessed individually. If service or maintenance is required, a particular level can be accessed safely without having to halt operations on the other levels. The levels are accessible via grated walkways for every Truck Shuttle path.

SMB is Your Project Partner for Storage Systems

SMB storage systems offer innovative solutions for the automated storage and retrieval of your raw materials or goods. We specialize in automated pallet storage systems, which we equip with our specially developed Truck Shuttle system.

The basis for optimal storage systems: the individual requirements of your company.

We develop automated storage and retrieval for deep-freeze conditions and as part of larger automated systems. Automated small parts warehouse, palletizers, or filling systems can be integrated. Conveyor systems ensure the connection of the individual parts of the internal logistics chain – creating fully automated intralogistics.

Feel free to contact us about your specific requirements.