High Performance in Your Production and Intralogistics

With state-of-the-art automation technology and software, we ensure that our palletizing systems perfectly integrate into your internal material flow and improve it through powerful pallet handling. Learn more about our various systems and machines:

Our Systems: These Palletizers Simplify Your Intralogistics

With state-of-the-art automation technology and software, we ensure that our palletizing systems perfectly integrate into your internal material flow and improve it through powerful pallet handling. Learn more about our various systems and machines:

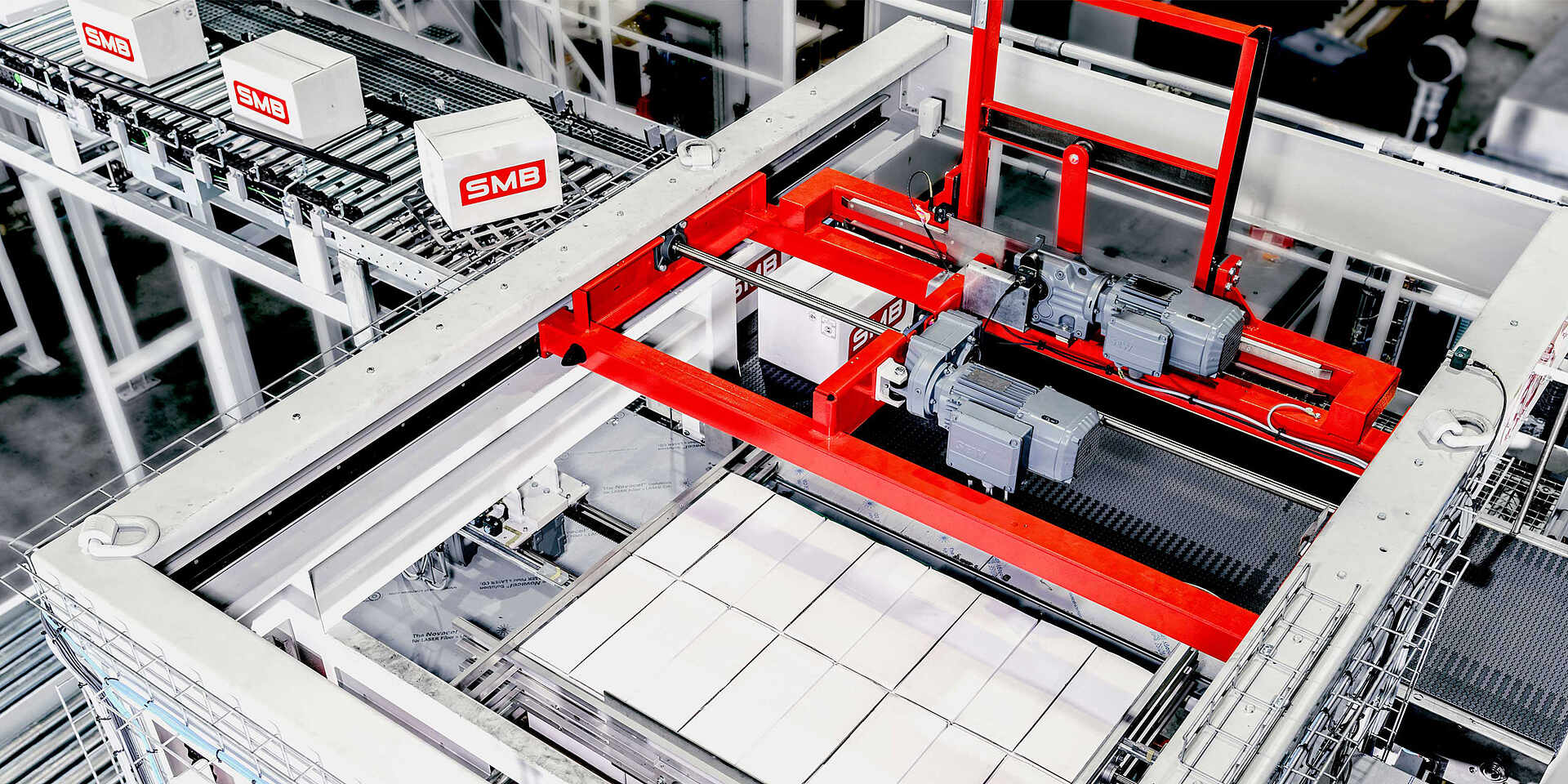

Layer Palletizers

Our layer palletizers can be optimally integrated into existing production logistics and allow for feedings or connections via conveyor technology on different levels. Due to their modular design, they offer a wide range of potential applications for your production and storage. Our layer palettizers are perfectly suited for high palletizing performance per hour and uniform packaging of piece goods.

Palletizing Robots

If the palletizing solution requires a compact setup, palletizing robots with the appropriate gripping element offer the most capabilities – even in tight spaces or low ceiling heights. The palletizing robot forms pallet units by picking up entire layers, rows or single items . Individual programming makes the robots a flexible solution for the palletizing process – adaptable depending on the types of containers, spatial limitations , existing processes and palletizing lines.

The Right Palletizer for Your Set-Up

Based on the type of cargo and your individual set-up, we help you select the appropriate palletization and conveyor systems, up to and including a fully automated pallet warehouse. This results in holistic systems. From the delivery of individual components to the dispatch of the finished, palletized goods, we organize your entire intralogistics process chain and ensure a smooth flow of materials.

Modular and Scalable

To help streamline logistics processes, SMB palletizers can be combined with one another and augmented with labeling machines, strapping machines, ring wrappers or magazines for empty pallets, for example. Whether it is conveyor system or storage technology - we make the connection.

- Gentle product processing: Our palletizing systems enable virtually contactless product handling.

- Optimum space utilisation: We integrate our solutions into your production to save as much space as possible.

- Energy efficiency and longevity: Thanks to the latest energy efficiency systems, the drives in our systems only consume energy when there is real power behind them.

- Potential for cost savings: Solid mechanical engineering and deliberately simple technology from SMB guarantee maximum availability and therefore a fast ROI.

- Improved working conditions: Our solutions relieve the burden on skilled workers and promote health and safety in your company.

- Independence from staff shortages: In times of a shortage of skilled workers, machines make an important contribution to keeping production processes running.

- Occupational safety: In the past, accidents often happened when loading pallets manually, but with the latest machines and their safety concepts, this is virtually impossible.

- Error reduction: Who hasn't experienced this? The wrong product was mistakenly placed on the wrong pallet during manual palletizing. The customer receives the wrong goods, another customer does not receive his goods at all. This results in expensive complaints and subsequent costs. Automated machines can reduce error rates.

- Perfect work results: Regardless of how your pallet is to be put together - whether nested, twisted or representative for direct placement at the point of sale - with SMB palletizers and the flexible software, there are virtually no limits to your product presentation.

- Independence from Staff Shortages: In times of skilled worker shortages, palletizers make an important contribution to keeping production processes running.

- Work Safety: While manual loading of pallets often led to accidents in the past, this is almost impossible with the latest palletizers and their safety concepts.

- Error Reduction: In manual palletizing, the wrong product can be placed on the wrong pallet by mistake. The customer receives the wrong goods, another customer does not receive his goods at all. This leads to expensive complaints and subsequent costs. Automated palletizing machines can reduce error rates.

- Perfect Work Results: Regardless of how your pallet should be assembled - whether interlocked, rotated or representatively set up directly at the point of sale - with SMB palletizers and flexible software, there are hardly any limits to product presentation.

We manufacture systems with high and low product infeed.

Want to palletize large quantities in a short time?

Robots add even more automation to your palletizing process.

Looking for maximum flexibility in palletizing?

Our systems effortlessly slide drums and canisters onto the pallet.

Interested in palletizing drums, buckets, canisters or pails?

Vacuum palletizers handle large, suction-capable containers.

Want to palletize canisters, plastic containers or metal drums?

Processing a Variety of Final Packaging and Containers with SMB Palletizers

From cartons, trays and folding boxes to barrels, canisters and large containers – our automatic palletizers can place a variety of containers and packages onto all common carriers and pallets. When planning a palletizing system, the primary focus is on the characteristics and shape of the products that you want to palletize automatically.

Neatly packed and sealed cartons with lids can be palletized with almost any of our palletizers, a layer palletizer for instance. Vacuum palletizers or palletizing robots may also be suitable for lower weight classes. One of the numerous applications of our systems: palletizing cardboard packaging with contents from the food industry, such as canned beverages or bottles of wine in boxes.

The American Case varies in size and is used as an outer carton in many industries, for example, in palletizing final packaging that goes to retail after labeling. Our palletizers are all designed to handle American Cases. It is important to ensure the cases are tightly sealed with packing tape. Additionally, the folding boxes should not bulge, for example, due to exceeding the fill quantity.

What Types of Palletizing Exist?

Palletizers operate using various palletizing methods. Full palletizers load the pallet directly, while layer palletizers prepare layers before moving them onto the pallet. In cases of limited space, robotic palletizing of loads may be advisable. A palletizing robot or articulated arm robot loads pallets with a gripper, allowing for the handling of differently sized units. A slide palletizer pushes containers onto a pallet.

The choice of palletizing method largely depends on the desired packing patterns on the pallet.

FAQ: Palletizers Explained

Here you will find the answers to all the questions we are frequently asked about this topic.

What exactly are palletizers?

Palletizers are machines designed to automatically combine items with load carriers, like cardboard boxes and pallets.

What does "palletizing" actually mean?

It is a logistics term, basically stacking stuff onto a pallet. Neatly packed pallets are a must in any warehouse for safety and efficiency. But manual palletizing is tough on workers, so automated systems are the way to go. They speed up loading and unloading, stacking of goods, and handling of load units, which simplifies warehouse operations.

Why bother with palletizing?

Palletizing ensures safe transport, storage, and standardized load units, worldwide. The goal? Optimize space on pallets to slash logistics costs.

What is the point of palletizers?

No one wants the grueling job of palletizing anymore. That is why automatic systems are the way to go. Once a system is installed, the benefits are self-evident.