Filling Canisters, Drums, and Palletized Containers

SMB filling systems are high-quality machines specifically tailored to meet your needs.

Our modular SMB system makes this possible. By combining individual components, we can offer you a customized machine solution. All of our systems are manufactured in Germany. In addition to configuring your personalized filling system, we also handle complete integration into your production environment. This includes the necessary conveyor technology to transport containers before and after filling. Our experienced engineering team and manufacturing almost all components in house has led to the great success of our filling systems.

We also provide custom solutions beyond our modular system.

Our filling systems can handle container volumes ranging from 2.5 liters to 1,000 liters of liquid.

These containers can include plastic canisters; buckets; hobbocks; open head, tight-head and lidded drums or IBCs. We tailor the exact performance individually for each customer, typically filling between 300 20-liter canisters to 20 IBCs per hour.

Our filling system can handle a wide range of containers. The range of products they can fill is also very broad.

This flexibility is made possible by our quick-change filling lances (dedicated product paths), which prevent cross-contamination. Our systems can also process materials with varying consistencies, from liquids to pastes and powders. As a result, they are widely used in the food, pharmaceutical, and chemical industries, where stringent hygiene and safety standards apply. For the filling of food and pharmaceutical products, SMB International can design the filling system cabins as clean rooms.

Our filling systems are also suitable for use in hazardous (Ex) areas.

They can safely fill toxic or flammable products in systems equipped with a containment booth (or cabin) and bung extraction.

The right filling method for every product

The choice of filling method depends on the product and container type. We offer three filling methods:

- Subsurface filling

- Subspout filling

- Above-surface filling

What differentiates these methods, and when should they be used?

Subsurface filling is used for products which foam, release gas or are otherwise sensitive, such as cleaning agents, solvents, and wood finishes.

Subspout filling is suitable for non-foaming, thin liquids like acids, alkalis and cooking oils.

Above-surface filling is used for non-foaming products such as paints, putties or lubricating greases.

All SMB filling systems can be equipped with these different filling methods.

Pallet Filling

Drum filling is an essential process for companies that manufacture and transport liquid or viscous products. Efficient and precise drum filling can save time and money while improving the quality and safety of products. We produce both simple filling stations with scales (semi-automatic drum filling systems) and fully automatic systems.

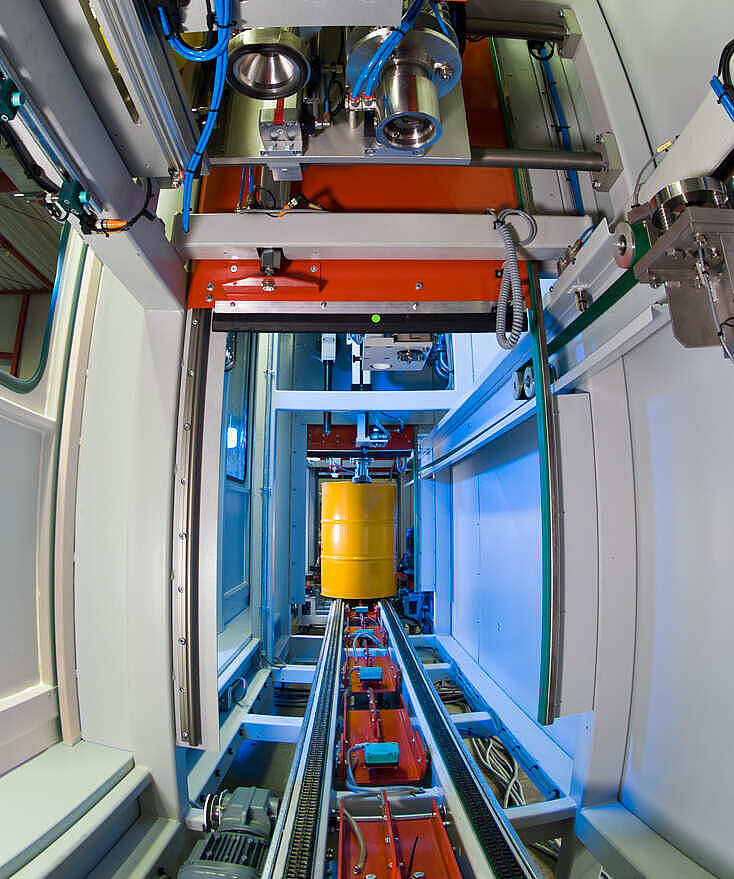

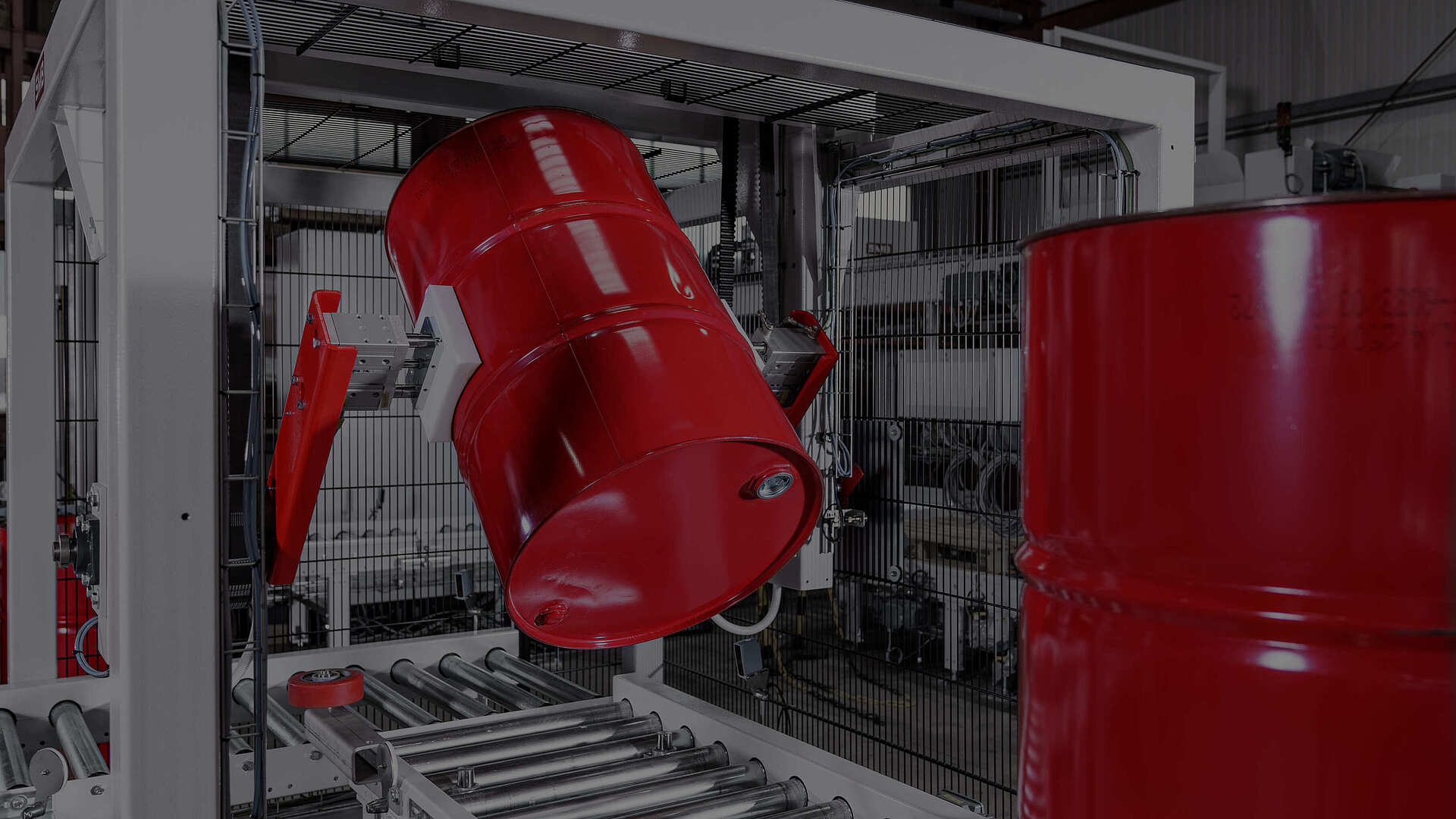

Drum Filling

Drum filling is an essential process for companies that manufacture and transport liquid or viscous products. Efficient and precise drum filling can save time and money while improving the quality and safety of products. We produce both simple filling stations with scales (semi-automatic drum filling systems) and fully automatic systems.

Canister Filling

Filling liquid substances into canisters is a crucial step in the manufacturing process of chemical, pharmaceutical and similar products. Precise dosing is essential to ensure consistent quality and safety. Our filling systems enable automated and efficient filling of canisters.

Extensions for Filling Systems

Our filling systems can be expanded with a variety of options. These include inspection and cleaning technology, as well as the integration of other equipment such as conveyor or palletizing systems. We are happy to advise you on the best combination for your business needs.

SMB is Your Project Partner for Filling Systems

SMB filling systems can process and precisely fill various container types, either individually or on pallets. The type and size of the containers, as well as the materials we fill, can vary.

The foundation for the optimal filling system: the specific requirements of your company.

We enable filling under clean room conditions and seamlessly integrate other systems like palletizers, depalletizers, and automated storage systems. When linked through conveyor systems, this creates a fully automated internal logistics chain.

Feel free to contact us with your specific requirements.